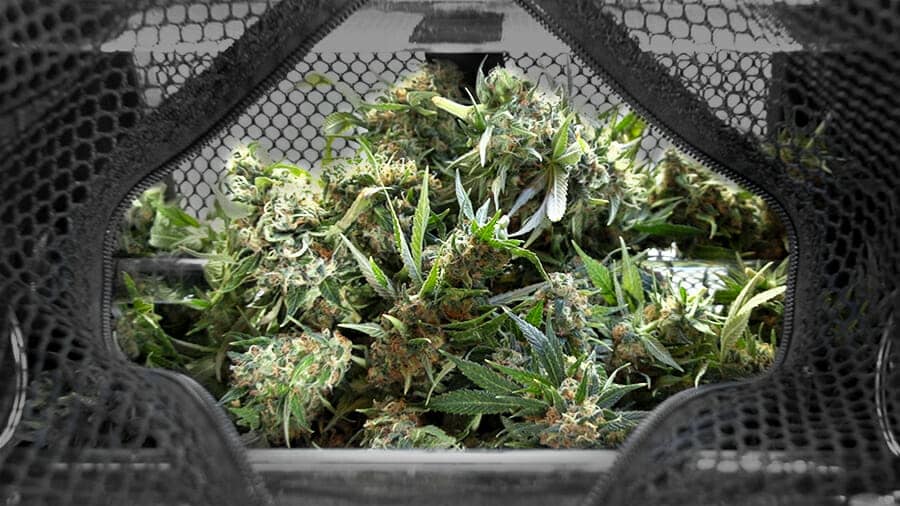

For those in the cannabis and hemp processing industries, “trimming” is a word fraught with concerns as to “how much time,” and “but, the quality is just not that good.” You’ve got harvesting of the crop, then you’ve got trimming of that harvest so it’s perfectly ready for high-yield extracting. It’s just like cotton: its harvesting of the crop and then separating the “lint” from the “seed,” so you have cotton ready to go to textile mills. The cotton out of the field has dirt, grass, leaves that needs to be removed, then sticks and burs are removed, then the load is crushed for oil, then the lint is cleaned of seeds, and only then is it ready to go to mills. With the invention of the cotton gin by Eli Whitney, the cleaning process for cotton was made easier, faster, more efficient. And today’s cotton gins are very advanced machines of extremely rapid cleaning power.

The cleaning or “trimming” of cannabis or hemp buds has undergone a similar revolution with the invention of the trimming machine. It is not as complex as cotton’s cleaning steps, but it, nevertheless, is necessary and contributes to the time and money of cannabis or hemp in making a profit. The first marijuana trimming machine was invented in 1997 by Ryan Hall. It was a revolutionary step and paved the way for several methods for trimming dry or web buds from cannabis or hemp harvests.

Now, in 2020, Cryo-Trim® from The Original Resinator company is at the zenith of the technologies for trimming harvests in the affordable, mid-price range. It is the outcome of our first tumble-style trimmer introduced in 2011.

At the heart of this methodology is the controlled introduction of freezing CO2 into the load of dry or wet buds needing to be trimmed or “cured,” and the timing of the curing process so that the trimming is done extremely well, yet is done as fast as possible so that many loads can be done in a day.

Cryo-Trim® is designed from the ground up to perform this curing function very fast, efficiently, and with the a super-clean yield that’s ready to go right into the extraction process.

Our discussion will continue in the next blog.

For bud trimming and extraction, go to our introductory page here,

and then give us a call to talk over what is the best TOR for you.