We inject liquid CO2 into our cryogenic chamber while gently tumbling material to allow exterior leaves to fall through our 1’4″ mesh screen. We rotate our drum for 30 seconds to one minute per pound on average. These micro CO2 injections brittle exterior leaves, quickly fracturing from flowers ready to collect for additional processing with a quick swap to one of our micron rated screens. This process is done with ease and efficiency, preserving structural integrity and botanical essence all while keeping trichomes intact and maintaining terpene profiles. We experience less than 1% total THC & CBD loss when trimming with CO2. We have Certificates of Analysis of before and after results when using The Original Resinator to trim with CO2. (We are always updating with additional data.)

We get 85% of the job done with unparalleled final results. All that is required is to buck down your material before tumbling and a light cleanup after. What typically takes as long as 8 hours of hand trimming to accomplish, can now be done with less than an hour of scissor time per pound including bucking on front end & light touch up on back. We say that your material comes out of the Resinator in the same condition it went in, only trimmed!

When trying to determine how much CO2 you will need to trim, it would seem like you might use less CO2 with our smaller OG model, but you have to quantify the capacity you are running with an XL to see that CO2 use is more efficient with the XL unit. This of course is relevant to the size of your operation. When running the OG model you only need to use half as much CO2 as the XL, however when running the XL you could run five times as much material at once. So for example, when trimming with CO2 utilizing the OG model you would get approximately twelve runs with the OG using a 50 pound tank whereas you will get six runs using the XL. But you would only get to run approximately eighteen pounds of material in the OG whereas you would get to run almost forty-two pounds with the XL in that equation. Refer to CO2 Frequently Asked Questions for more information about CO2.

The amount of CO2 available in a cylinder can vary due to different factors: The type of extraction or trimming you are doing. The length of the hose, the length of your blast and the tank’s size. Ambient temperature conditions of your environment and you Resinator itself. The amount of material loaded also plays a role.

Example 1- With the standard high pressure hose included at 30 seconds per blast and a 50lb Co2 Siphon tank, you can anticipate an average of 6 minutes of effect and approximately (12) 30 second shots.

Example 2- With the standard high pressure hose included at 30 seconds per blast and a 25lb Co2 Siphon tank, you can anticipate an average 3 minutes of effect and approximately (6) 30 second shots.

These are guidelines on average experience. Keep in mind that roughly 10% of the gas remaining in a spent tank will not come out in liquid form. When you can no longer see the gas entering the chamber it is a good indication that there is no longer liquid co2 left to dispense.

Liquid C02: When trimming buds/flowers, consumption is approximately 1-2 Lbs. of Liquid C02 per 1 Lb. of biomass. However and to ensure that you don’t run out of Liquid C02 we recommend having 2 Lbs. of Liquid C02 per each 1 Lb. of trimming of buds/flowers.

Cost per Lbs of Liquid C02 is approximately $1 per Lbs at retail, while larger volumes of delivered C02 can be purchased for as low as $0.25 per Lbs pending your local supplier. We have customer accounts set up with a number of national gas suppliers with pre negotiated discount rates. Inquire with our team for a reference or for any inquiry regarding C02 questions and common FAQ.

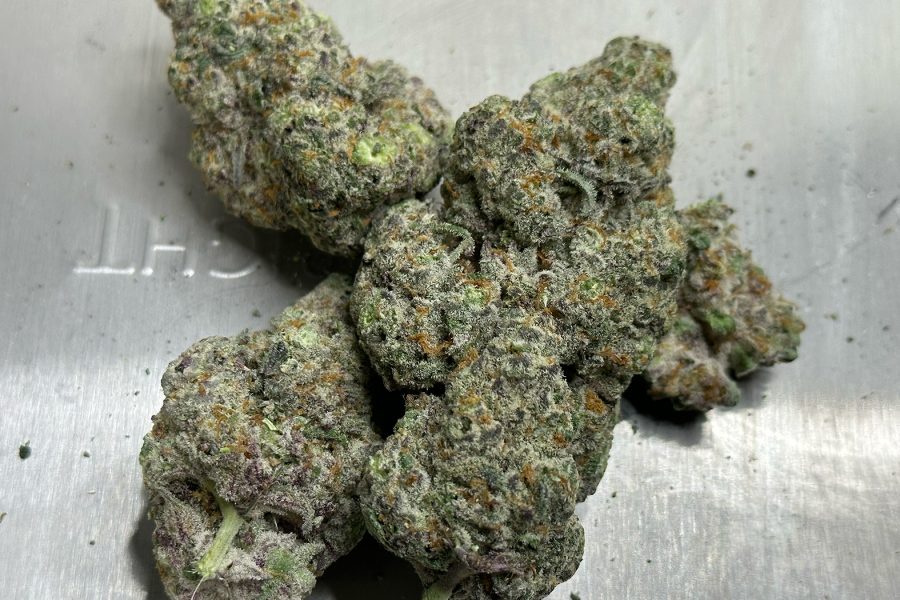

Capacity: As a trimmer, the OG model has a 1.5 lb capacity while the XL model has a 7 lb capacity. If you load 5-7 pounds, then you spin for 5-7 minutes. This is a guideline, as not all flowers are created equal. Often only 30 seconds of tumble time per pound is all that is needed, this of course is directly related to how well the product has been prepped as well as its state of dryness or how brittle the material you are working with is. We say that your flowers come out the Resinator the same way they went in, only trimmed. When tuning into what works best for your product, we suggest a smaller test run before large batching so you can get familiar with the process and material you are handling.

Refer to our Extraction and Trimmer Guide for suggested run times, speeds, and load sizes. The whole bodied, high quality trim that remains after CO2 separation is preferred over scissored or bladed trim due to the lack of chlorophyl, cellulosic material and plant particulates found through trimmed clippings as a result of utilizing a bladed surface, making for better extracts and pre-rolls. Experience the Resinator difference…!

*WHEN UTILIZING CO2 BE SURE TO OPERATE IN A WELL VENTILATED AREA.

Harvesting cannabis at the right time is essential for maximizing the aroma, flavor, and effects of each strain. Harvest cannabis buds too early and you risk a lower trichome quality

The sugar leaves on cannabis plants offer myriad possibilities for growers and processors when you know how to use them to their full advantage. These small leaves can be used

A professional cannabis trimming service can be helpful if you don’t have the space, time, equipment, or personnel to complete this vital task in-house. Or perhaps your farm or facility

In today’s hyper competitive cannabis world, every cultivator is looking for an edge to achieve a higher retail price point for their dried buds while avoiding any unnecessary steps or

Cannabis extracts that are rich in terpenes are more flavorful, aromatic, and attractive to connoisseurs. Terpenes are the volatile compounds (present in essential oils) that give plants their flavor and

There are several reasons people might not want to wear gloves when trimming cannabis buds, such as a perception of having greater control over the bud without gloves, more tactile