We inject liquid CO2 into our Resinator chamber while gently tumbling material to allow exterior leaves to fall through our 1’4″ mesh screen. We rotate our drum for less than a minute per pound. Micro CO2 injections brittle exterior leaves, quickly fracturing the leaves from the flowers ready to collect for additional processing with a quick swap to one of our micron rated screens.

This process is done with ease and efficiency, preserving structural integrity and botanical essence all while keeping trichomes intact and maintaining terpene profiles. We experience less than 1% total THC & CBD loss when trimming with CO2. We have Certificates of Analysis of before and after results when using The Original Resinator to Cryo-Trim® with CO2.

After installing desired mesh screen to Resinator drum, load your material directly into drum and insert into Resinator chamber. Begin drum rotation, inject liquid CO2 for up to 30 seconds to 1 minute (pending model). Intermittent manual rotations of the internal drum for 1-2 rotations while on the low setting during injection of Co2 will reduce attrition rate. Allowing biomass rto reach ideal “ice cream” temperature before beginning tumble will maximize the Cryo-Trim® function and retention rates of A and B bud ratios. Once optimum internal temperature is reached, then allow material to tumble for 30 seconds to 1 minute per pound of biomass loaded. We recommend the less is more technique until optimum results are achieved, upon which your recipe can now be repeated while catering to strain and condition of the flower. After material has been tumbled to desired satisfaction, remove drum and empty processed buds onto the workstation lid and collect your finished flowers. The separated leaf remaining in the Resinator chamber can be collected for additional processing into our patented Cryo-Sieve® process for secondary refinement into your subsequent downstream extracts. Ease of operation makes for a quick clean up and reset. The same process applies to live’ and dry, plant trimming & separating.

We get 85% of the job done with ease and efficiency. All that is required is to buck down your material before tumbling and a light cleanup after. What typically takes as long as 8 hours of hand trimming to accomplish, can now be done with less than an hour of scissor time per pound including bucking on front end & light touch up on back. We say that your material comes out of the Resinator in the same condition it went in, only trimmed!

As a trimmer, the OG model has a 1.5 lb capacity while the XL model has a 7 lb capacity. If you load 5-7 pounds, then you spin for 5-7 minutes. This is a guideline, as not all flowers are created equal. We actually recommend cutting that guideline in half until you have found the sweet spot for your particular cultivar. Often only 30 seconds per pound is optimal, this of course is directly related to how well the product has been prepped. The whole bodied, high quality trim that remains after CO2 separation is preferred over scissored or bladed trim due to the lack of chlorophyll and plant particulates found through trimmed clippings as a result of utilizing a bladed surface, making for better extracts and pre-rolls.

Refer to our Operating Guide for suggested run times, speeds, and load sizes.

Our Instruction Manual & Instructional Videos help to explain this process step-by-step.

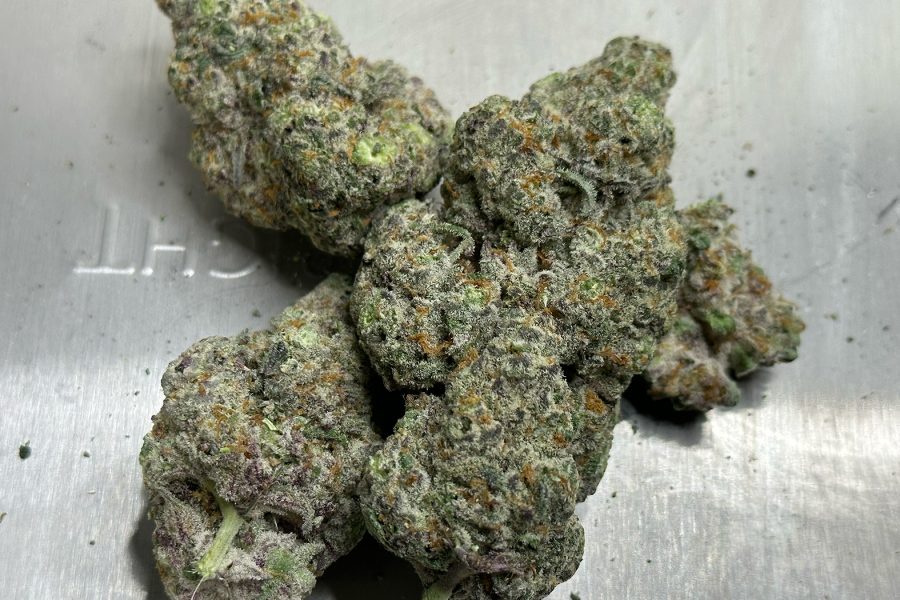

Please note: The Original Resinator is a bladeless bud trimming system and utilizes liquid C02 as a freezing agent and minimizes any attrition of the quality flower trimmed or processed through our patented CRYO-TRIM® process. The ’TOR’, CRYO-TRIM® system freezes, fractures and trims by utilizing temperature control between 10 to 30°F, (ice cream temps). These temperatures protect the valuable elements and vitality within your finished flower such as but not limited to the trichomes, potency, terpenes, and aroma/nose while trimming the flower. Utilizing our slow rotation of our processing drum, the optimum frozen temperatures causes the external leaves to become just brittle enough to fracture and fall from the flower, exposing a perfectly trimmed flower and without upsetting the trichomes or terpene content. Aggressive scissor work during a common hand trimming process of flowers may often cause damage. The “TOR” system trims with the rise and fall of the flower creating a pristine finished product without shaping or contouring your flower/buds. The ‘TOR’ system optimizes your finished product to garner maximum quality for wholesale and retail sales.

There are several reasons people might not want to wear gloves when trimming cannabis buds, such as a perception of having greater control over the bud without gloves, more tactile