Freeze drying is revolutionizing the post-harvest workflow for cannabis growers and processors, but you need to know how to do it correctly to maintain product quality from live material to

Cryo-Trim® with CO2

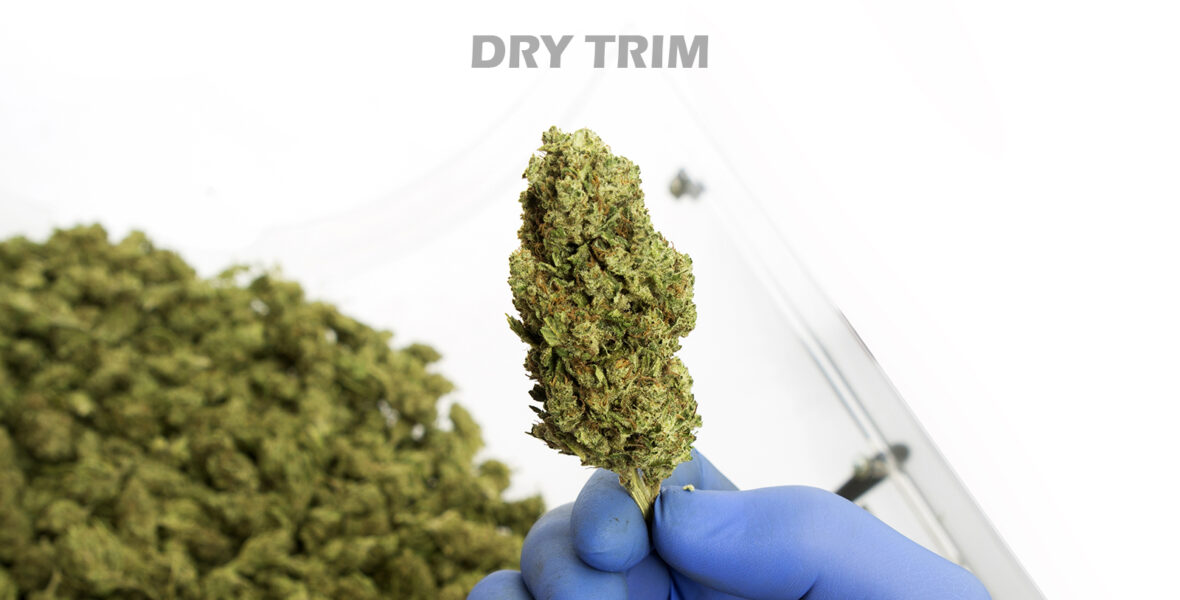

Dry Trim / Wet Trim / CO2 / Crop2Cure

Before

After

This Multi functional, blade-less tumble trimmer is ideal for commercial growers who want to trim with maximum efficiency and minimum waste. Flash freeze assisted tumble leaf extraction does 85% of your trimming. The high quality nylon mesh screen cradles the flowers as they tumble, and separates the sugar leaf from the dried flowers. Leaving only touch up (crows feet) left, and trichomes and flowers preserved. Trims up 40+ pounds per hour, manicuring 5-6 pound loads per 5-7 minute cycle!

Easily collect trim material after it has fractured and fallen through our high quality 1/4” & 1/2” mesh screens. Additional separation applications may include de-seeding, removing big leaves, recapturing dry-ice, isolating small flowers and other similar uses. Our unique design allows for easy loading and unloading of your harvested flowers and processed material.

Trimming & Separating in one easy process

– Microinjections of liquid CO2 brittle exterior leaves allowing them to quickly fracture and fall from the flowers. By momentarily flash freezing the biomass, the process results in clean manicured buds in an incredibly short time.

– When DRY trimming with CO2, there is no need to change your standard drying and curing operating procedures. The natural dry process allows the water molecules within the flower to cure organically, so your flowers will be as you are accustomed to.

– Lyophilization, aka Freeze Drying or Wet Curing is required when doing a WET trim with CO2. It’s only when doing a wet trim with CO2 that we have displaced the oxygen in our chamber and lowered the temperature below the freeze rate of 32°F which results in the cellular wall the plant rupturing. This means that the biomass must be preserved before it has a chance to oxidize and discolor. Deep freezer storage and sublimation via freeze drying represents a sea change in the way cannabis is preserved, processed, packaged and consumed.

– The Original Resinator Cryo-Trim® methodology employs a patented protocol using liquid carbon dioxide that provides an exceptional manicure of the outer leaves resulting in a near perfect product.

– Apart from the visual look and appeal, Cannabis and Hemp plant parts get infected with bugs and molds that take even a bigger bite since the end product is unsafe and unacceptable for consumption. Better sanitization is achieved by least handling contact and processing exposure thus assisting in regulatory compliances and clearances

– The entire process has smaller footprints and better performance metrics than the other machine options capable of similar workflow throughput.

- Trims Live’ & DRY flowers.

- Efficiently trims & separates up to 40+ pounds per hour.

- Gently tumbles with no metal blades for minimum bruising of trichomes & flowers.

- Don’t settle for less than the best.

- Lid also serves as a sanitary workstation.

- CO2 flash freeze application utilized correctly, aids in leaf extraction and separation.

- Preserve precious botanical essence by flash freezing with efficiency and ease.

- Round, clear convenience.

- Easy to load, clean and reload.

- Industry game changer.

- Save time and money while increasing productivity.

- Multi-Use integrated function and rapid workflow.

- Maintain an ideal environment for proper separation.

- Optimize performance with continuous temperature control.

Experience the Resinator difference!

Trim a pound per minute…! When you load your machine with cannabis or hemp flowers, you can inject liquid Co2 into the chamber and achieve very cold temperatures. This allows the exterior leaves to become just brittle enough to fracture off of the flower and fall through the mesh screen without damaging, bruising or compromising the integrity of the flower. When trimming with CO2 we recommend “ice-cream” temperature. That’s between 10°F and 30°F. Temperatures for a tumble trim don’t fall to the sub-critical levels that help dislodge trichomes from flowers. After liquid CO2 exposure, the freeze effect on flowers and biomass normalizes in a matter of minutes with no loss of vitality or damage to terpene profiles. When prepared properly, we often experience results that exceed our expectations. The better bucked and big leaved your material, the less time necessary to achieve desired results, only adding to increased processing times and production volume. A slight investment of time on the front end pays off in spades on the back end.

We are often asked, doesn’t freezing the buds knock off the trichomes? That is a good question and common misperception. The short answer is NO IT DOES NOT… We only go to ice cream temperatures of 10°F to 30°F when trimming, that coupled with short run times delivers VERY favorable results. As opposed to when we are doing a kief separation we are going to sub-zero temperatures as low as -85 °F. We find that trichomes don’t start falling off until negative temperatures below -10 °F are reached. And that’s only on traditionally dried and cured flowers. Wet/Uncured flowers tend to let us utilize even lower temps without sacrificing any cannabinoids. When trimming with Co2 we lose no more than the average handling as a hand manicure loses when utilizing scissors, trim trays, totes or bins and finger hash which is typically lost from general processing. We have run hundreds of 5lb tests utilizing the metric system with two independent labs to demonstrate how effective our Cryo-Trim™ process is. There are COA’s on our website that demonstrate we are losing on average of .03 to .08% total THC and CBD loss from raw flour to post Resinator trim.

Temperature accompanied with time spun are the primary contributors to the difference between kiefing aka biomass reduction and trimming with co2. For example, when we are kiefing we go to subzero temperatures as low as -85°F. Whereas when trimming we only go to ice cream temperatures, being 10° to 30°F. Trimming we only spin for 1 pound per minute on average. Whereas when kiefing we will spin on average from 10 minutes to an hour accompanied with sub zero temps. (Pending the application we modify parameters.)

Live rosin cartridges are a premium SKU that will set your brand apart from competitors in dispensaries. Not only are live rosin vape carts extremely flavorful thanks to their high

After ice water extraction, it’s essential to dry bubble hash thoroughly before pressing rosin, selling it as-is, or using the hash in edibles or topicals. When done properly, you can

Dry sift rosin offers an excellent opportunity for turning regular trim into valuable SKUs, and with the right equipment, high-quality dry sift rosin can be created quickly and with minimal

Pressing kief into rosin is a straightforward process, but if you want to achieve a top-shelf extract, there are a few tricks of the trade you’ll want to know. From

Full-melt hash is the caviar of cannabis extracts. Maybe you’ve seen the words “full melt” plastered across hash containers at your local dispensary, or maybe you have customers of your