In today’s hyper competitive cannabis world, every cultivator is looking for an edge to achieve a higher retail price point for their dried buds while avoiding any unnecessary steps or complications. One increasingly popular method for accomplishing exactly this is freeze drying cannabis. This cutting edge method involves a controlled moisture removal process that dramatically reduces the time to market. It can also significantly increase cannabinoid and terpene retention and eliminates the possibility of pest contamination and continued microbial growth.

Properly freeze dried cannabis is commonly known as “live dried” for the same reasons “live resin” and “live rosin” are denoted as such. In fact, one of the most amazing attributes of live dried cannabis is the fact that it provides a new use case for fresh frozen cannabis. Traditionally, producers and processors are relegated to two primary directions downstream when working with fresh frozen material: hydrocarbon extraction and live bubble hash, which in turn is most often converted into live concentrates. Fresh frozen buds can now be preserved via cold storage and processed on demand over a year after the initial harvest.

In this article, we’ll explain how freeze drying compares to the traditional drying and curing process and how growers of any scale can leverage this technique to make a better product.

What Is Freeze Dried Cannabis?

Freeze dried cannabis is the flowers or buds of the cannabis plant that have had their moisture removed to ideal levels with the use of a freeze dryer instead of being traditionally dried and cured. Despite the fact that freeze drying weed sounds like a radical concept to many growers today—and has historically been considered experimental—the basic concept has been scientifically refined to produce highly potent and smooth smoking products that consumers love.

Among the many interesting things that happen to cannabis when it’s freeze dried is a cessation of shrinkage, so that the flowers retain the same size and shape that they had in the garden. When done properly, this not only extends the shelf life of the cannabis but also allows growers to simply freeze their crop upon harvest and dry it on demand. That translates to fresher deliveries as-needed to dispensaries instead of having to batch dry a harvest all at once, which quickly degrades. When frozen cannabis is properly stored, it can last for years with minimal to no degradation.

Perhaps the most important benefit of freeze dry cannabis, however, is the proven increase in terpenes and cannabinoids. In some cases, freeze dried buds are as much as 15% more potent than traditionally dried and cured plants from the exact same harvest. This is a direct result of maintaining the cold chain from freshly freezing a cannabis harvest all the way through the lyophilization process. The cold temperatures mitigate the loss of volatile terpenes and prevent chemical changes to the cannabinoids, essentially preserving the live biomass exactly as it was in the garden.

The drying method most growers employ (using large rooms and air circulation) certainly has been mastered over time and produces excellent results when done well. However, a traditional drying and curing process takes anywhere from 2-6 weeks whereas freeze drying cannabis can produce a cured, shelf ready product in as little as 48 hours.

How to Freeze Dry Cannabis

The drying and curing process when cannabis is freeze dried takes a path that’s largely similar to how modern live ice water hash is produced. When a harvest begins, it starts with bucking and big leafing like you traditionally would, but then the flowers must be bagged and frozen whole. After cold storage in the deep freezer, when ready, the buds are cryo-trimmed to remove the remaining sugar leaves and are then quickly put into a pre-frozen freeze dryer.

This is where things get interesting, and even though regular freeze drying machines can be used in some cases, they need to be modified to do the process correctly. Harvest Right Scientific freeze dryers are necessary for home growers or boutique producers, but if you’re looking for a commercial-scale solution, Cuddon Freeze Dry HiLyph edition units are the best option around. When you’re using a Harvest Right, the standard Pharmaceutical units won’t suffice, you really do need a Scientific Model combined with a DigiVac vacuum bleed controller and The Original Resinator’s lyophilization standard operating procedure. Taken all together, this method is called Crop-to-Cure®.

Freeze dryers basically put the drying and curing process into the fast lane by taking the buds through cycles of freezing under deep vacuum pressure that creates sublimation, which is where the moisture goes from a solid to a gas state and bypasses the liquid phase entirely. The pre-freezing process ruptures the cell walls of the plant which enables the moisture to escape. Since it’s deeply frozen, the cannabinoids and terpenes are much better preserved than their traditionally dried and cured counterparts.

There are options on the market today that can do anywhere from 1 to 225 dried pounds per day in a single freeze dryer, so freeze drying cannabis can be done viably at scale in any sized facility.

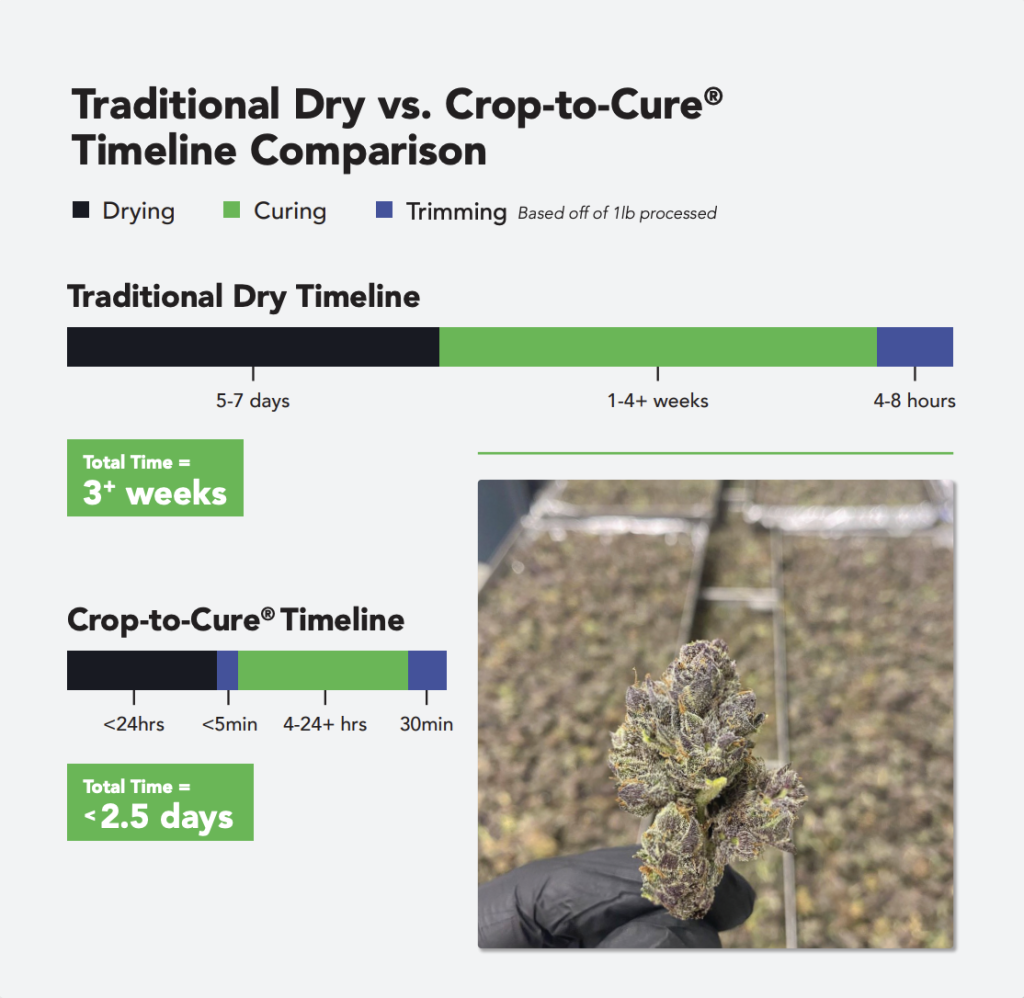

A timeline breakdown of freeze drying cannabis compared to traditional hanging and drying.

Advantages and Disadvantages of Freeze Drying Cannabis

As with almost any practice, freeze drying weed has a number of distinct advantages, and a handful of disadvantages as well. Here, we’ll break down what to expect when you freeze dry cannabis.

Advantages

- Results in a premium product that preserves more cannabinoids and terpenes than the traditional air drying and curing process

- Increases terpene retention for a stronger, deeper aroma that justifies premium price points for producers

- Can be completed in as little as 48 hours, including curing time, which is a fraction of the time compared to any other cannabis drying method

- Requires significantly less facility square footage, which is at an absolute premium in licensed operations

- Prevents shrinkage or loss of size (resulting in bigger buds) and also preserves the original color, which increases bag appeal for consumers

- Prevents any mold or microbial growth due to the extremely cold temperatures and deep vacuum pressure during freeze drying

- Extends the shelf life of the product and enables cultivators to dry cannabis on demand; frozen buds can last for a year or more with minimal to no loss in final quality

- Reduces labor costs by streamlining the entire process into a much shorter time frame

- Creates a smoother smoking dried flower that reduces the chance of tussiculation and airway irritation for the consumer

Disadvantages

- Requires upfront investment to do, especially at scale

- Demands specific power requirements and ambient room conditions

- Requires cold storage infrastructure with backup generator power sources

- Must be done under carefully controlled parameters and standard operating procedures

- Freeze dried cannabis has a different structure than some consumers are used to

How to Store Freeze Dried Cannabis

Freeze dried cannabis is easily stored just like traditionally dried and cured buds. However, as soon as the buds are out of the freeze dryer, they will want to absorb moisture in a climate controlled, oxygen rich environment. A short burping and curing process is advisable to get the best end result.

Since the freeze dryer conducts the primary drying process, no secondary drying is necessary. Simply store it the same way you would any other dried cannabis or hemp flower: in turkey bags or airtight containers out of direct sunlight at room temperature. As we’ve mentioned before, you can perform this process in batches so that you have a fresh, live dried product on shelves on demand for the best consumer experience.

Frequently Asked Questions about Freeze Dried Cannabis

Can you use regular freeze drying machines for cannabis?

The most affordable freeze dryer that can be used for this cannabis freeze drying process is a Harvest Right Scientific model, which is available in a standard, large, or XL size. It must be combined with our DigiVac StrataVac vacuum bleed controller and Crop-to-Cure® SOP package for the best results.

Do you need to trim the buds before freeze drying them?

No, but it is the recommended order of operations for multiple reasons. Before freeze drying cannabis or hemp, they should be trimmed using a cryo-trimming method since the plants have not been dried yet. This removes all of the sugar leaves and manicures them correctly so when they come out of the freeze dryer, they’re ready to go.

How long does it take to freeze dry cannabis?

Freeze drying cannabis takes approximately 24 hours, plus or minus, depending on how dense your buds are and how much you packed into each tray. We always factor in a little extra time to be conservative.

Are there different settings for different strains?

Sometimes you may need to adjust your settings when freeze drying weed, but only in certain circumstances such as when you’re going from very dense buds to airy flowers on the next cycle.

Can you freeze dry hemp?

Yes, you absolutely can freeze dry hemp and it’s faster than any other drying method out there, just like with cannabis. All of the same great benefits associated with freeze drying cannabis also apply to hemp.

How long does freeze dried cannabis last?

The shelf life of the cannabis plant once it’s been freeze dried is typically longer than that of air dried and cured flowers because the freeze drying process helps prevent oxidation. We say anywhere from 3 to 6 months is ideal, but over a year is entirely possible.

Do you need to rehydrate freeze dried cannabis before smoking it?

Typically you do not, as long as you are doing your cannabis drying process properly with the Crop-to-Cure® method. Certain strains can require modest rehydration immediately after exiting the freeze dryer, which can be done using humidity packs.

How do you cure freeze dried cannabis buds?

Freeze dried cannabis buds do not require extended curing; the active and potent enzymes that break down the chlorophyll complete their work much more quickly after freeze drying thanks to the chemical changes involved in the process. It only takes a few hours to a day for buds to cure after freeze drying, depending on the environmental conditions and the strain.

What products can you make with freeze dried cannabis?

While the majority of live dried cannabis is smoked or vaped as dry flower, the porosity of freeze dried flowers (the freeze drying process opens the cannabis plant’s cell walls) makes them especially conducive to hydrocarbon extraction methods.

Do you lose total crop weight compared to traditional dry and cure processes?

No, the final weight is equivalent because the moisture is being removed to the same degree. We are simply removing the water via sublimation instead of evaporation.

Has live dried cannabis been used to win awards?

Yes, in fact! The Original Resinator and Industry Processing Solutions in conjunction with Compound Genetics and Node Labs won first place for Innovative Product: Consumable with their Perzimmon #2 (Rainbow Cheddar x Gastro Pop) freeze dried cannabis at The Emerald Cup 2023.

Upgrade Your Buds With Freeze Dried Cannabis

It’s virtually guaranteed that freeze drying is slated to be a sea change in the way both cannabis and hemp operators look at how to dry their crop to bring it to market. In our white paper on the topic, we’ve been able to demonstrate how much of an economic and profitability impact this can have for cultivators.

As anyone who has been in the industry a long time knows, however, change takes time. It’s hard for those who have legacy mindsets and methods they love to try new things, particularly when their facility is not a new buildout.

When all of the factors are weighed and measured, it’s clear more business owners are going to take the leap. Not to mention consumers are always looking for something new to try, especially with an enhanced product, which is becoming less common as markets continue to mature. If you’re interested in learning more about freeze dried cannabis, talk to us!