COMMERCIAL SCALE CANNABIS DRYING & CURING

Freeze Drying Cannabis and Hemp Isn’t Radical, It’s The Future

Why Use Cuddon HiLyph Freeze Dry Solutions?

HL-50

HL-600

HL-1200

Talk to a Freeze Dry Expert Today

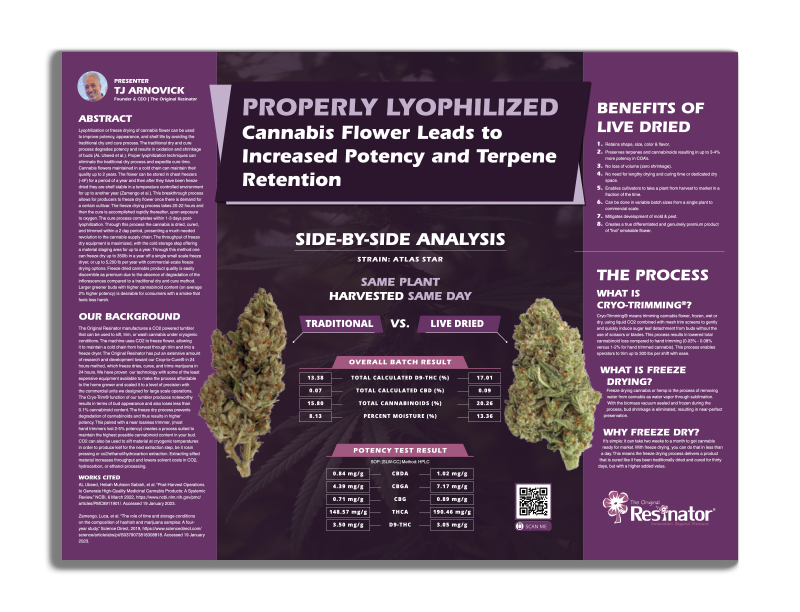

Why Live Dried is Better

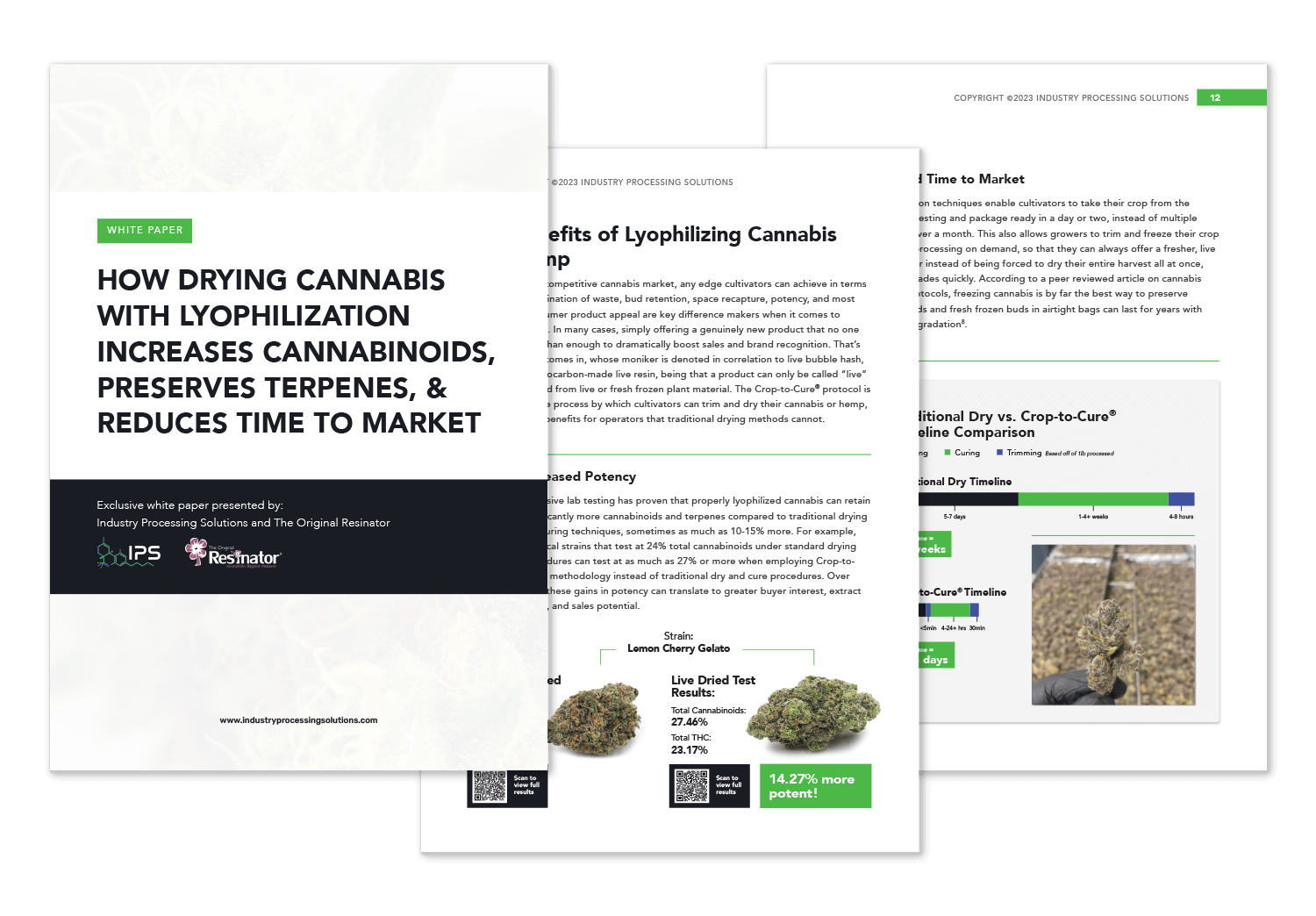

The exact same plant’s test results when comparing traditional dried vs. Crop-to-Cure®

Lemon Cherry Gelato

TRADITIONAL DRIED

TEST RESULTS:

24.03%

20.74%

Lemon Cherry Gelato

LIVE DRIED

TEST RESULTS:

27.46%

23.17%

Lemon Cherry Gelato

TRADITIONAL DEAL

TEST RESULTS:

24.03%

20.74%

Lemon Cherry Gelato

LIVE DRIED

TEST RESULTS:

27.46%

23.17%