In this exclusive Original Resinator guide, we’ll walk you through what fresh frozen cannabis is, how the method of using freshly harvested buds is optimal to preserve terpenes, what commercial as well as boutique operators use it for, and much more.

Fresh frozen weed has numerous applications from premium live dried cannabis flower to high quality extracts of all kinds. It’s prized by product manufacturers the world over as a top sought after starting material to make cannabis concentrates with primarily, but that demand is starting to shift with the recent upward trends in consumer taste preferences towards seeking lyophilized buds as opposed to just strictly traditional dried varieties.

What is Fresh Frozen Cannabis?

If you’ve ever had live resin, live rosin, or live dried cannabis, then you’ve been lucky enough to enjoy the end result of a cultivator or extractor using fresh frozen cannabis in their process. It’s made using fresh cannabis buds that have had their fan leaves removed and then are subsequently completely frozen whole.

If you’re sitting here wondering why would a grower freeze their plant material in the first place, it’s because when the trichome glands and trichome heads of the fresh buds are carefully stored in subfreezing temperatures, they preserve the rare terpene and cannabinoid profiles that are widely seen as unrivaled by cannabis connoisseurs.

Regular dried and cured buds have different aroma and flavor profiles due to the standard drying process itself, wherein many of the delicate, highly volatile terpenes that are only present in live plants disappear along the way.

Additionally, cannabis or hemp plant material that’s in an airtight bag and frozen fresh can last for an extraordinarily long time which gives operators the ability to use it on demand as opposed to all at once like you would have to otherwise.

Benefits of Fresh Frozen Cannabis

Fresh frozen material offers a wide range of unique benefits that cannabis businesses can leverage to grow their product lines, improve their extraction methods, and build a more highly sought after brand.

Key fresh frozen cannabis benefits:

- Fresh buds maintain their true “live” essence from the garden all the way through to their extracted or live dried form

- Extracted SKUs made with fresh frozen typically retail for 50-100% more than their conventionally non-frozen material derived counterparts

- It serves as the premier plant material for every solventless extraction method in order to make the best ice water hash, live sift, and live rosin possible

- Fresh frozen weed and sugar leaves are also a highly desirable for hydrocarbon extractors to make live resin of all textures with

- It only requires freezer space for long term plant matter storage that can be deployed for extracts and live dried depending on market trends

- The fresh frozen method requires significantly less facility square footage to process since traditional hang drying and curing is not required

Best Strains for Fresh Frozen

Thankfully great fresh frozen weed can be made from just about any decent quality cannabis or hemp plants, regardless of strain. That said, here are some of our very favorite strains that you can pursue for your own garden or operation.

Wedding Cake – super popular for a reason, Wedding Cake is one of the top strains used to make bubble hash and has been crossed with endless other strains

Super Boof – a true crowd pleasing citrus-forward fruity, high yielder that does great in extracts or live dried and is quickly becoming a top strain worldwide

Apple Fritter – this delicious cross of Sour Apple and Animal cookies makes for incredible live resin or live rosin and whose top phenotypes are coveted by growers everywhere

Watermelon Zkittlez – the name alone should be enticing enough, but Watermelon Zkittlez is one of the absolute kings of fresh frozen strains due to its desirability in extracts of all kinds

Sour Diesel – despite its status as a true classic, Sour Diesel still holds sway as a top strain to freeze, especially for live dried applications

How to Process Cannabis from Harvest to Fresh Frozen Material

Thankfully processing live cannabis plants into fresh frozen is a pretty simple process, but with some very important steps along the way that need to be followed closely. Above all else, time is of the essence during the harvest process, because oxidation and degradation begin immediately once the plants have begun being harvested.

Fresh frozen weed processing steps:

Step 1 – Prep Work

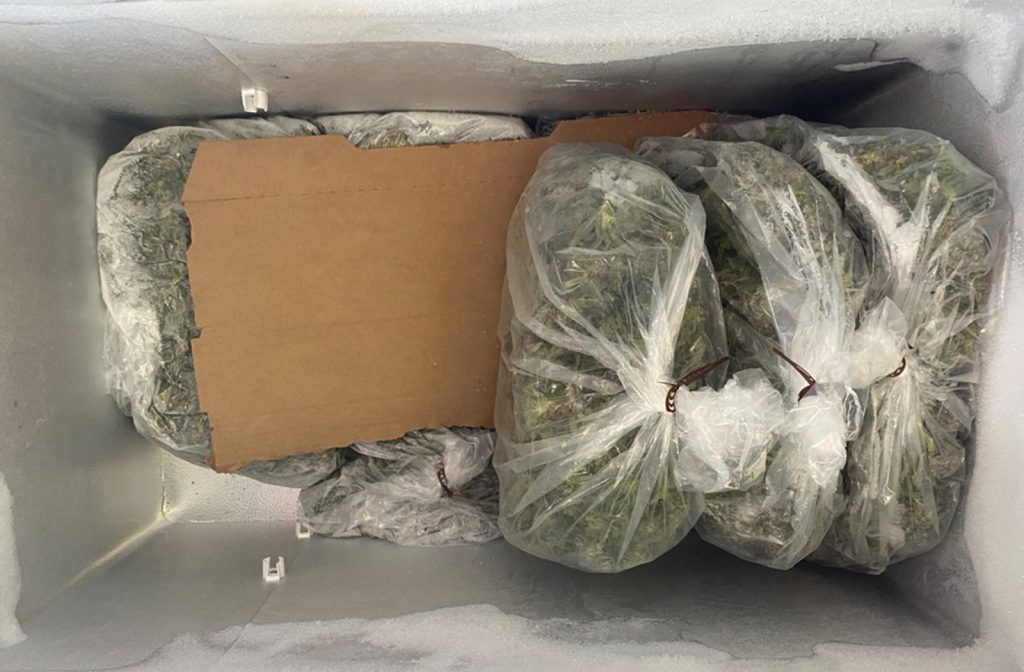

Prepare your plants by stripping them of their fan leaves, then buck them, and finally put them into airtight turkey bags as quickly as possible. Defanning plants before chopping and bucking them is strongly advised. Be careful not to overstuff the bags, the buds should be loose and have room for air exchange.

Step 2 – Freezing

Take your filled bags and put them into a clean food grade bin. Then, put the loosely packed bins in an industrial freezer that can consistently maintain 0°F or lower. You do not need to go lower than that temperature-wise. Commercial chest freezers also work well but are not as efficient in terms of storage space per square foot. Make sure your material is completely frozen before using it.

Step 3 – Storage and Use

Fresh frozen cannabis can last 1 to 2 years or longer when stored properly as outlined above. As long as the cold chain is properly maintained, your terpenes and cannabinoids will remain almost perfectly preserved. When you’re ready to use your fresh frozen, do not let it thaw – use it immediately for whichever application you intend to.

Applications for Fresh Frozen Buds

When it comes to fresh frozen, there are two primary pathways it can be used for: extraction and live dried applications. As mentioned previously, concentrates (both solventless and hydrocarbon-based) have historically been the most common use cases, but now freeze dried weed, aka live dried, is quickly rising in popularity.

Solventless and Hydrocarbon Extraction

While you can make great concentrates and extracts with cured flowers or trim, the very best solventless and butane-made SKUs start with fresh frozen. Connoisseurs and even casual consumers recognize that the flavor profiles of live extracts are superior, so processors everywhere have started incorporating it into their product lineups.

In the solventless space, fresh cannabis buds are frozen and used to make live dry sift, live bubble hash, which are typically used for rosin pressing as the final result product. Rosin made with live material can be processed into many different textures from cold cure to fresh press and even jams. Conversely, fresh frozen puts the “live” in live resin (which is made using butane or other mixtures of hydrocarbon solvents) and these SKUs have become ubiquitous in most US markets.

Live Dried Smokeable Flower

The other burgeoning application for fresh frozen cannabis is live dried. This is a new cutting edge form of smokable cannabis or hemp flower that is carefully dried and cured using specialized freeze drying techniques instead of employing traditional air drying and curing methods. It happens in about two days as opposed to weeks or over a month, which gives cultivators enormous latitude to release batches on demand very quickly.

It also creates extremely smooth smoking buds that retain their original size, shape, color, and live aroma which is particularly appealing to consumers. Best of all, getting started making live dried doesn’t require an enormous investment, and cultivators can get started for around $16,000 for a turnkey package, which includes a full SOP.

Tips for the Best Results with Fresh Frozen Cannabis

As with all things, there are better and worse ways to go about doing them. Processing your crop into fresh frozen is no different and we’ve compiled a helpful list of tips and tricks to get the most out of your subsequent harvesting, extraction, and live dried efforts.

- Try to start with quality material. The fresh frozen applications we mentioned before are best suited with at least decent quality harvested cannabis as a starting point in most cases. Hash makers especially are keen to use the very best material they can for solventless extracts specifically.

- Don’t overpack your bags. Whether you’re using your fresh frozen for extraction or live dried, surface area is key. Make sure to not stuff your freezer bags, otherwise your buds will turn into frozen bud bricks. Your turkey bags should be loosely packed and closed airtight before they go into the freezer.

- Maintain the cold chain. It’s imperative to keep your buds cold immediately after bagging all the way through to the final SKU and beyond. Above freezing temperatures are the enemy to delicate terpenes. You can use dry ice in coolers to keep fresh frozen cold during transportation if needed, but never let the bags directly touch it.

- Get your process down. It might take a few tries but make sure to have a protocol for your fresh frozen processing efforts in the garden. Don’t pull your plants down without a plan!

- Don’t forget to talk about it. When you make live extracts or live dried flower, make sure your marketing reflects why those products are so special by explaining to your customers what it is and why “live” products are so important.

Fresh Frozen Cannabis Opportunity

Talk to a grower in almost any legal or legacy cannabis market and you’ll hear the same thing: people want to buy some or most of my crop frozen these days. Whether it’s for extracts or live dried, the demand for fresh frozen cannabis is increasing just about everywhere given its enormous utility to make premium quality concentrates and a whole new class of dried smokeable flower. Best of all, it provides a huge opportunity for virtually all plant touching businesses: cultivators to make live dried and to sell it to other businesses, manufacturers to extract with it, and dispensaries to highlight live products at the top of their shelves.

If you’ve been curious about how to profitably make or use fresh frozen, contact our experts today to learn more about all of the different ways Original Resinator’s post harvest solutions can improve your operation’s bottom line!