Dewars & Cylinders come in many different sizes for various applications. They are designed to maintain extremely cold temperatures for cryogenic storage of liquid gases—including nitrogen, oxygen, argon and carbon dioxide (CO2). When using The Original Resinator, we utilize Liquid CO2. CO2 is available in several grades. Medical, Beverage/Food, and Industrial. We have found Industrial CO2 to be clean & efficient. No residual by product has shown up in any of the extensive testing we have done. We have also had no reports of any of our customers having issues with industrial CO2.

Medical grade CO2 has 99.99% purity rating. Both Beverage and Food grade CO2 both have a 99.95% purity rating. Industrial CO2 has a 99.90% purity rating. The other .09 – 1% is made up of impurities such as hydrocarbons or nitrogen. The slight difference between Industrial-grade CO2 and Food grade CO2 is the type of test that are done to qualify CO2 as Beverage gas compared to Industrial-grade. Food grade CO2 is in fact Beverage grade CO2, they are equivalent. Its all about the purity of the gas. All CO2 is made the same (to the best of our knowledge). Its all about how the CO2 is stored, handled and transferred. The FDA has put compliance laws on Food aka Beverage grade CO2, making distributers store the gas in specific tanks just for Food or Beverage grade. Food grade CO2 is pure enough for human consumption based on FDA compliance. Food-Grade, anything (in the US) means special requirements on transport and handling, which implies more expense. So even though the same plant may produce it, the pipes leaving the plant have to be Food grade, the tanks the product goes into have to be Food grade. The non-food grade version will go through less expensive /less-maintained/less-cleaned pipes and into similarly treated containers. Medical grade CO2 is not reasonable to get for consumption purposes.

When talking about cylinders we must first consider high pressure vs. low pressure. HPA (High Pressure Air) tanks are pressurized up to the tank’s rating of 3000 psi or 4500 psi (Pounds per Square Inch). The pressure is then regulated through the tank’s regulator down to 850psi (High Output) or 450psi (Low Output). High pressure vessels are generally referred to as tanks, whereas Low pressure containers are generally referred to as dewars. Many people use the word “dewar” to describe a “liquid cylinder”, and vice versa. There are some key differences and they come in a wide variety of options.

While dewars might seem complicated at first, in reality they’re safe and easy to use once you understand the basics. If you’re interested in talking with an expert about how liquid CO2 trimming and sifting can radically improve efficiencies at your operation, contact us today to talk to one of our post-harvest processing experts.

What is a Gas Cylinder?

A compressed gas cylinder or high-pressure tank is a pressure vessel for storage and containment of gases at above atmospheric pressure. High-pressure gas cylinders are also called bottles. Inside the cylinder the stored contents may be in a state of compressed gas, vapor over liquid, supercritical fluid, or dissolved in a substrate material, depending on the physical characteristics of the contents. A typical gas cylinder design is elongated, standing upright on a flattened bottom end, with the valve and fitting at the top for connecting to the receiving apparatus. High pressure tanks most commonly do not have a siphon tube installed. A high-pressure Co2 cylinder with a Siphon tube installed in tank is required to dispense CO2 in it’s liquid form. Also known as a “Co2 Siphon Tank” or “Dip Tube Tank“. The Siphon tank has a tube that runs down the center to dispense the liquid Co2. These tanks come standard with a CGA-320 outlet, which is compatible with the high-pressure hose provided with each Resinator machine purchase. When placing your Co2 tank order with your local supplier, make sure you ask for a Siphon tank.

What is a Dewar?

Dewars are non-pressurized vessels, like a Thermos Bottle. They typically have a loose fitting cap or plug that prevents air and moisture from entering, yet allows excess pressure to vent. Laboratory Dewars have wide-mouthed openings and do not have lids or covers. These type of dewars will not hold liquid CO2 and are often used with Liquid Nitrogen. Laboratories primarily use these small containers for temporary storage.

What is a Liquid Cylinder?

Liquid Cylinders are pressurized containers specifically designed for cryogenic liquids. Low-pressure Liquid Cylinders let you with withdraw liquid and/or gas. A Liquid Cylinder has valves for filling and dispensing the cryogenic liquid, and a pressure-control (pressure builder) valve with a brittle rupture-disk as backup protection. Although high pressure cylinders with siphon tubes can disperse liquid CO2, due to volume limitations in commercial applications we recommend utilizing 350psi high-pressure cylinders similar to what is pictured below. A 25psi for example will not work for Resinator purposes as the pressure is to low to effectively disperse CO2 for desired results. Pending on your local gas supplier, these tanks come standard with a CGA-320 or a CGA-622. If outfitted with a CGA-622 an adapter will be required for use with a Resinator.

We will now focus on Liquid Cylinder operations

for use with The Original Resinator.

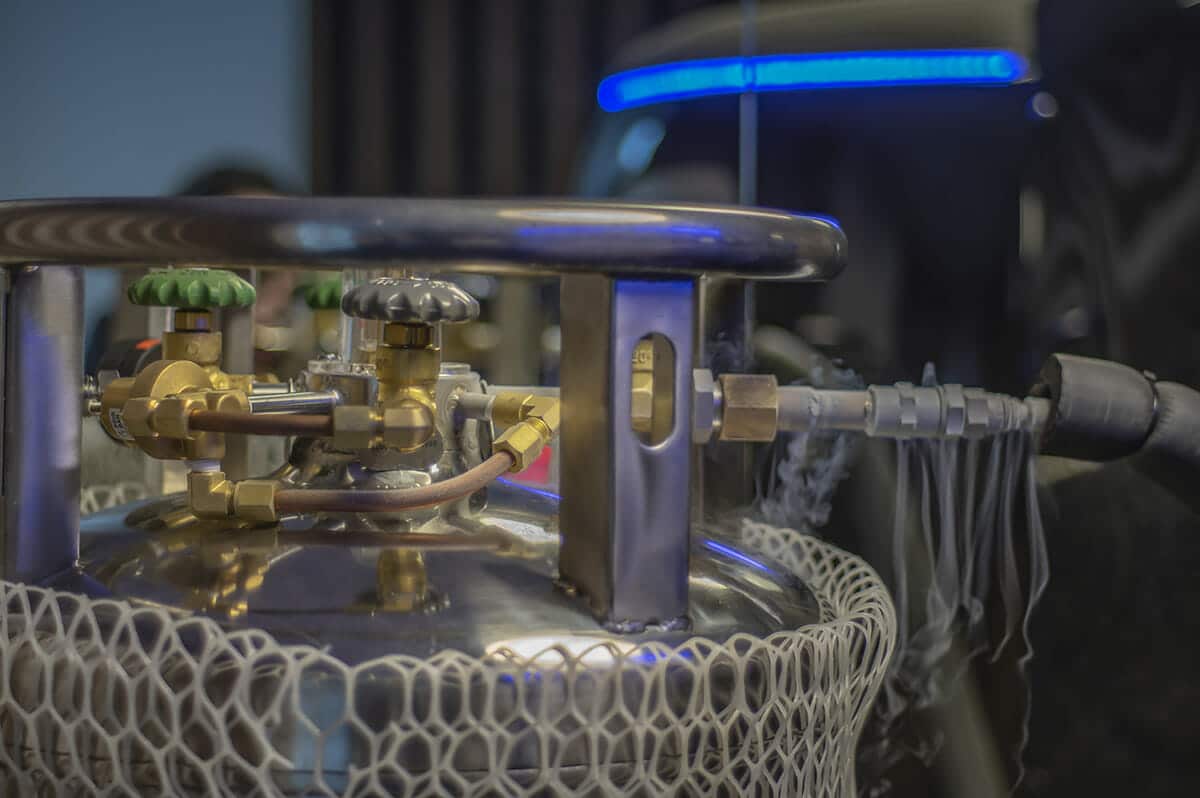

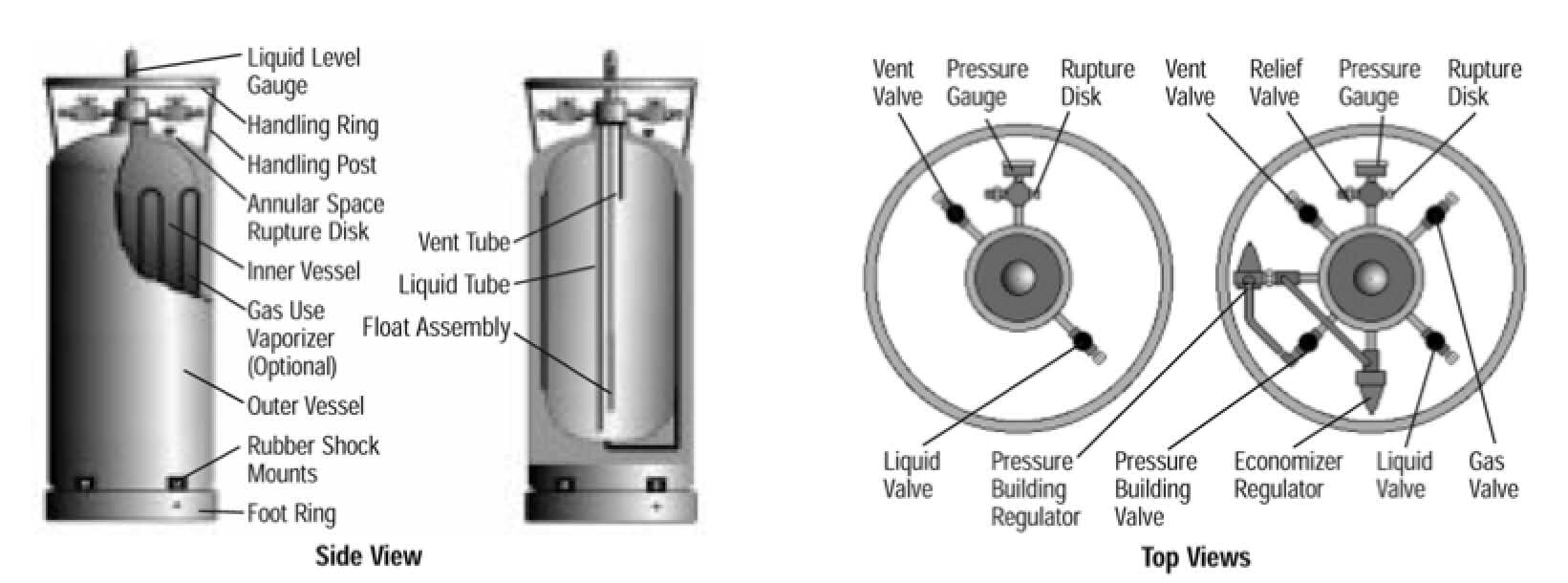

When utilizing The Original Resinator in a commercial application, CO2 Cylinders similar to the Liquid Cylinders pictured above are very popular. This is do to the nature of large volume production needs, cost savings and convenience. Typically there are three valve handles, a pressure gauge, and a CO2 level indicator located on the top of the Liquid CO2 Tank. These valves handles should be labeled as Gas/Vent, Liquid, and Pressure Builder. We only use the Liquid supply to operate The Original Resinator. We will cover each of these below.

Before we dive into the tank valves we will briefly review the two types of outlets found on Liquid Cylinders, the CGA-622 and the CGA-320 outlets. Tanks outfitted with a CGA-622 or a female end, will need a CO2 liquid cylinder adapter, an essential component for hooking up your Resinator to a low-pressure liquid cylinder. If your cylinder has a CGA-322 outlet then your Resinator coil assembly included with your machine purchase is all you will need.

The top of a liquid cylinder tank – a standard CO2 source for Resinator machines – can be a confusing sight at first. Each outlet and valve serve a particular purpose, so each are important to understand. Since each outlet and valve should be clearly labeled, let’s zero in on the most critical one for a Resinator machine: the Liquid outlet. This is the source of our liquid supply of CO2. This outlet is the one you’ll use for all Resinator machines, but it’s important to know that you may need a particular CO2 tank adapter to hook up to the outlet properly. (Adapter not provided with Resinator purchase.) Until recently, Dewar/Liquid Cylinder tanks came standard with liquid CO2 outlets called a CGA-320, allowing you to then attach a hose between the outlet and Resinator machine. That’s changed. Liquid cylinder tanks are now coming standard with a female CGA-622 outlet, and therefore require a new CO2 tank withdrawal adapter, the CGA-622 x 320, to fit properly to a hose. If your liquid cylinder has a CGA-622 this Liquid Dewar adapter is now a necessary part of a secure setup so that your machine functions properly. It’s a minor change, but it’s important to make sure that you’re using the correct fitting when dealing with liquids and gases at such pressures.

*CGA-622 X 320 Liquid Cylinder withdrawal adaptor.

(Pictured below and available through our online store.)

When making the leap from high-pressure cylinder use to low-pressure large volume cylinders, you may want to consider a longer custom fit high-pressure hose set up. Your local gas supplier should be able to help you source whatever parts you may need for your application.

*Customized high-pressure hose & filling options. (Pictured left)

Once you have identified the Liquid valve and are using withdrawal adapter (if necessary), it’s time to attach the hose. The CO2 supply hose is threaded onto the valve outlet, being sure to use the appropriate sealing washer, and tightening to mitigate any leaks. Being that the Resinator is not a closed loop system, a few CO2 leaks are nominal. Although leaks will contribute to raised CO2 levels, which should always be monitored. When ready to operate the Resinator, open the Liquid valve fully by turning counter clockwise. The pressure builder is a very important component in achieving the proper Resinator operating pressure. We can monitor this operating pressure by observing the pressure gauge located on the top of the Liquid CO2 Tank. Ideally the operating pressure of the Liquid CO2 Tank is 330-350 psi. This is achieved by opening the pressure builder valve prior to operating the Resinator.

Notes:

- The relief valve may hiss for pop if the pressure build beyond the relief valve rating and this is normal.

- The Liquid CO2 Tank is equipped with a pressure relief valve that is fixed to open at 350 psi. (Be sure to get a 350 psi tank.) The pressure relief valve is in place to ensure the internal Liquid CO2 Tank pressure does not exceed 350 psi. As you approach the ideal operating pressure the relief valve may open slightly and release CO2 gas. Although this is sometimes noisy this is no cause for alarm, simply close the pressure builder valve by turning clockwise.

- A tank with a dent or dig may not work as good.

- You must make sure the pressure build is on 300- 350 range.

- TECH TIP: Building the pressure to the proper level may take up to an hour, so it is suggested that the Pressure Builder valve be fully opened one to three hours before use.

- Never use the gas side, purge tank before liquid use.

- Tanks are extremely heavy and a tank dolly is recommended when moving.

Know Your Gauges and Valves

Tell help you see the forest from the trees, take a look a the diagram below to become familiar with the important parts of your liquid cylinders. Be sure to get request

Pressure Control Valve and Rupture and Burst Discs

The Pressure Control Valve is mounted on the same stem as the Pressure Gauge. Recommended set to open at 350 psi, the Pressure Control Valve works in conjunction with a Rupture Disc in the inner tank. As a secondary relief device, there is also a Burst Disc on the outer tank to protect the space between the inner and outer tanks from high pressure.

Liquid Contents Gauge

In the center of the tank there is a Liquid Contents Gauge. This can be a float-type gauge that provides an approximate indication of the tanks contents. These are generally very sufficient, however if you want more accurate measurements, try a gauge that uses differential pressure to determine liquid levels. These modern displays also contain graphical digital displays to give you precise measurements. Plus they often have the intelligence to eliminate the need for lookup charts. In addition, many of these digital liquid content gauges have telemetry capabilities to make it easier to monitor levels of key cylinders.

Economizer Circuit

If you don’t use the a cylinder for several days, pressure will continue to rise at a rate of apox. 30 psi per day because a small amount of heat will leak into the inner tank. This heat vaporizes a small amount of liquid and causes the pressure to slowly rise. The pressure may build up to the design of your Pressure Control Valve. The valve will then open and vent gas to the atmosphere. To minimize losses from this venting, the cylinders have an Economizer Circuit. The Economizer Circuit comes into action when the pressure reaches psi setting. At this point, the regulator allows gas from the top of the tank to flow through the internal vaporizer out of the Gas-use Valve to the target system. This reduces pressure in the inner tank and minimizes losses from venting. When pressure normalizes, the Economizer Regulator closes and the cylinder then deliveries gas by drawing liquid through the Vaporizer Circuit. The Economizer Regulator should have a set pressure 15 psi higher than the Pressure Building Regulator.

Pressure Gauge

The Pressure Gauge is probably the one you will look at first and refer to most frequently. This gauge indicates gas pressure inside the inner tank. Since cryogenic liquids are actually liquefied gases, pressure within the tank will constantly increase as the laws of physics transform the cold liquid into warmer gas. Fortunately, this pressure will help you withdraw the liquid or gas from your cylinder. But for most applications, the pressure inside the tank must be artificially maintained. A Pressure Building Circuit can automatically do that.

Opening the Pressure Building Valve located at the top of the tank takes liquid from a line that runs from the bottom of the inner tank, and passes it through the Pressure Building Coil attached to the inside wall of the outer tank. As liquid passes through the Coil, it is vaporized by the heat of the outer tank. The resulting gas is fed through the Pressure Building Valve and Pressure Building Regulator, into the inner tank causing the pressure to rise. We recommend operating your cylinder at 350psi to avoid any clogging/freezing issues while under operation with your Resinator.

Gas-use Valve and the Vaporizer Circuit

When pressure has been built, you can draw gas from your cylinder by opening the Gas-use Valve. Opening this valve lets the pressure in the tank force liquid up a withdrawal line, and then down into a vaporizer coil. Once again, heat is conducted through the outer tank walls to the vaporizer. As the liquid moves through the coil, it is vaporized by this heat. The resulting warm gas flows up through the Gas-use Valve out to the user system to complete the Vaporizer Circuit. Generally a single stage regulator is attached directly to the Gas-use Valve to reduce the supply pressure to match your application’s requirements. This valve dispenses compressed gas and does not dispense liquid gas. We will not use this valve in operation with the Resinator machine.

Liquid-use Valve

To withdraw liquid from your cylinder, first close the Pressure Building and Gas-use Valves. Then open the Liquid-use Valve to allow head pressure in the tank head to force liquid up to withdrawal tube, and out the Liquid-use Valve. Pending how the tank was filled by your supplier, there may be excess compressed gas which will need to be exhausted before you will see the CO2 dispensed in it’s liquid form. Purging your tank before use to ensure liquid CO2 is being dispensed prior to attaching your high-pressure hose is recommended. This is done by simply opening the valve until you can see the gas in a fog form as opposed to the compressed gas which looks like air. If a greater liquid withdrawal pressure or rate is required, a qualified service agent can adjust the Pressure Building Regulator.

Watch out for Frost and Water

Because the Pressure Building Vaporizer contains cold liquid, it cools the outer tank and it is perfectly normal for frost to form on the outside of the cylinder. During a prolonged high-draw, the gas-withdrawal temperature to fall considerably and the outside of the cylinder will be very heavily frosted. This frost eventually turns to water that can damage flooring, as well as seep into your facility’s interstitial space to create more damage to other systems. A Drip Tray can save you a lot of headaches and hassles. Place your liquid cylinder and/or its vaporizer on a pan or tray to catch the water as the frost evaporates. The higher the tray’s lip, the less worry you’ll have about water damage.

Let’s recap…

The more you know about your dewars / liquid cylinders, the more you don’t have to worry about them. If you think something has gone wrong, just remember:

- Be sure to get a 350 psi Liquid Cylinder from you supplier and the correct CGA adapter, if needed.

- The Pressure Gauge indicates pressure inside the inner tank. Opening the Pressure Building Valve increases tank pressure to normal operating levels.

- The Gas-use Valve allows gas to flow from the tank.

- The Economizer Circuit minimizes product loss.

- To draw liquid, close the Gas-use and Pressure Building Valves, and open the Liquid-use Valve.

- If you need to know exactly how much liquid is in your cylinder, use a Digital Gauge.

- Frost and ice are nothing to be scared about. But use a drip tray or pan to avoid water damage.